Transferware helped manufacturers produce very pretty pottery and porcelains quickly and less expensively than the previously hand painted pieces.

Next time you see a piece of Transferware, pick it up — look for the seams and notice how some line up perfectly and some are just a tad off. You might also notice the border running off the edge. Each piece is only as good as the Transferer — all hand applied one plate, cup or saucer at a time.

What type of Transferware are you buying?

Usually each piece of Transferware tells a story. By looking at the back stamp, a collector can check the pattern name, the initials or name of the maker and sometimes the name of the town where the factory is located. Sometimes there are no back stamps and only the Stilt marks are showing — these are three little dots in the glaze that held the triangular spur pieces and separated the plates in the kiln.

Why does the color blue seem to be used so frequently in Transferware?

Blue comes from cobalt and was the only color at first that would survive the high temperature of the glaze process. The rich blue color is associated with famous historical plates and also in the early Flow Blue. Blue Willow is one of the most popular patterns of transferware. It was initally designed by the famous Thomas Minton around 1790.

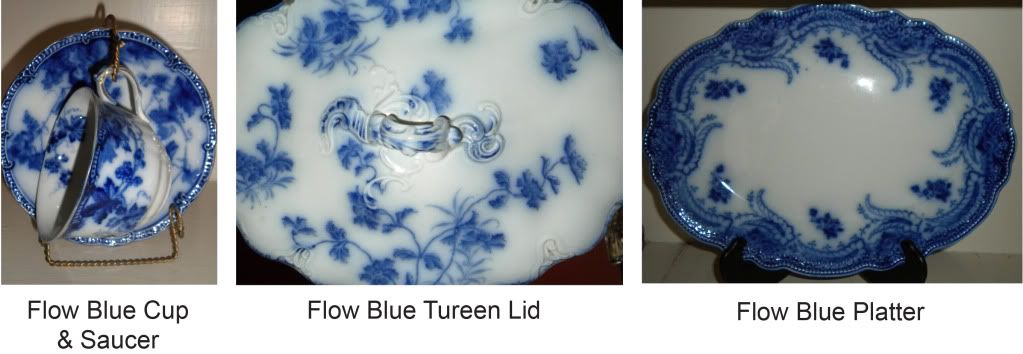

Why does some of the blue transferware look blurred?

This blurred "look" is actually called Flow Blue. In 1545 in Saxony, a potter named Schurer used cobalt oxide and noticed that this blue soaked into the porous ware and blurred a bit in the glazing process. In 1820 it was discovered that the blue would "flow" by adding lime or chloride of ammonia to the sagger while glazing. The blurring covered printing faults and stiltmarks. When cobalt is initially applied it is brown and only turns blue in the firing process. Some think that Flow Blue china was a mistake and it eventually become a collectors item. This is not true — it was a deliberate process that is highly sought after by collectors.

Stay tuned for more posts on pottery, porcelains and the history of Blue Willow china.

No comments:

Post a Comment